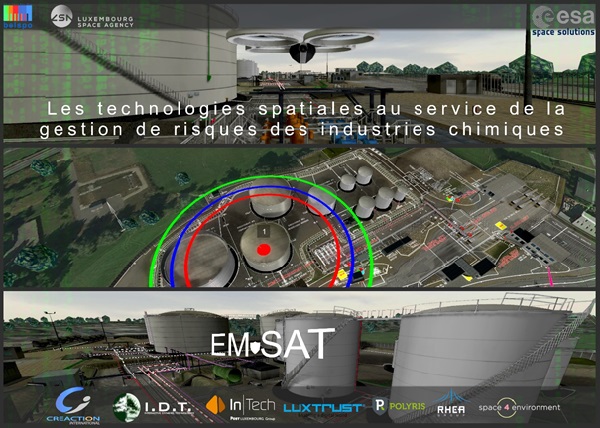

Creation International has announced the development of EM-SAT (Advance Data Management for Chemical Industry), a Belgo-Luxembourg project aimed at directly responding to the safety management needs of the chemical industry.

EM-SAT is currently being developed as an innovative product / service directly responding to the safety management needs of the chemical industry and thereby significantly strengthening the safety of the populations which are directly or remotely concerned in a given territory. Belgium and Luxembourg have more than 220 SEVESO (high threshold) chemical industrial sites on their two territories. This industrial demonstration project was selected by the European Space Agency (ESA) and by both the Luxembourg Space Agency (LSA) and the Belgian Federal Science Policy Office / Space Department (BELSPO). The ESA, through its ARTES / BASS (Business Application Space Services) programme is financing 50% of this research, feasibility and demonstration project for a duration of two years.

The Belgo-Luxembourg industrial partnership is composed of eight private and public companies which have been studying and developing for the past year the complementarities and advantages of each of their services dedicated to the high security of employees and installations.

The partners are:

- IDT (LU): 3D industrial imaging and provider of the 3D integration software METIS

- LUXTRUST (LU): high security for data, people and trusted services, Europe approved

- SPACE4ENVIRONMENT (LU): "high definition and interpretation" of satellite imagery

- CREACTION INT Lux (LU): transfer of AMALFI, a space data quality control software

- INTECH (LU): design and development of digital systems and custom software solutions

- POLYRIS (BE): design office for industrial risk prevention and management, spin-off from UMons

- RHEA GROUP (BE): engineering office for security solutions in the space field, specialized in cyber security and present with an office on the ESEC site in Redu

- CREACTION INT Belgium (BE): design office in industrial creativity and innovation, coordinator of the EM-SAT project

The EM-SAT platform is set to become one of the main tools for fulfilling SEVESO obligations of making sure that all necessary measures to prevent major incidents and to limit their consequences are taken and information regarding accidents can be timely and easily accessed by the parties having proper rights to such information, as outlined in the directive. The platform is expected to significantly improve collaboration, access to information, decision-making and security of crisis management operations as well as crisis prevention and training tools, including scenario planning and procedures.

EM-SAT will be tested through demonstration scenarios initiated within environments able to show the main features of EM-SAT monitoring and response management in the context of SEVESO incidents. Components of the EM-SAT platform will reactively and proactively protect the crisis management network from cyber-attacks. Cyber security incidents will be simulated and handled within the EM-SAT demonstration environments with reactive response plans, while the system will be proactively protected through a dynamic risk assessment engine. Access to information by the various stakeholders will be secured by strong digital identification of these parties and the chemical infrastructures involved.

The customers targeted by the EM-SAT partnership are the entities and production / distribution sites of the chemical industry which have the obligation to comply with the European SEVESO directives. There is a strong concentration of these companies in the Benelux and its surrounding region. The final three demonstrations will focus on three well-known sites in the Luxembourg province of Belgium and in the Grand Duchy of Luxembourg. They meet the following needs: access to the earth observation images and their selective and secure provision to the involved stakeholders; improved data services including sensors and tags that can be controlled by the staff of the industrial plants; interoperability of all deployed systems and connectivity layers; a central management hub; ease and speed of deployment of remediation actions; highest levels of proactive and reactive protection in terms of cyber security.